Categories

Recent Posts

Tags

The key components of a bus air conditioning system

On: 2024-11-20

Posted By:

Hit :

The key components of a bus air conditioning system are critical for ensuring effective cooling and comfort in the cabin. Understanding these parts can help diagnose issues, improve performance, and ensure proper maintenance. Below is a breakdown of the essential bus air conditioner parts and their roles:

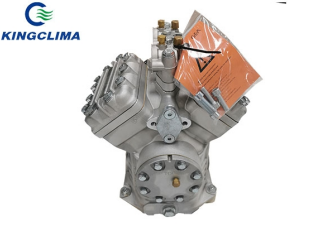

1. Compressor

- Role:

The heart of the air conditioning system, responsible for compressing refrigerant and circulating it through the system.

- Key Features:

- Driven by the bus engine or an electric motor.

- Maintains the refrigerant under high pressure.

- Importance:

Without the compressor, the refrigerant cannot circulate to remove heat from the cabin.

2. Condenser

- Role:

Converts the high-pressure refrigerant gas into a liquid by dissipating heat.

- Key Features:

- Located at the front of the bus, near the radiator, for maximum airflow.

- Uses external air or fans to cool the refrigerant.

- Importance:

Essential for releasing heat and ensuring efficient cooling.

3. Evaporator

- Role:

Absorbs heat from the bus cabin and cools the air.

- Key Features:

- Located inside the cabin behind the dashboard.

- Cold refrigerant flows through the evaporator, cooling the air blown over it.

- Importance:

The primary component for reducing cabin temperature.

4. Expansion Valve or Orifice Tube

- Role:

Regulates the flow of refrigerant into the evaporator.

- Key Features:

- Expansion valve adjusts flow based on temperature.

- Orifice tubes provide a fixed flow rate.

- Importance:

Controls refrigerant pressure and temperature, ensuring optimal cooling.

5. Receiver-Drier or Accumulator

- Role:

Removes moisture and contaminants from the refrigerant.

- Key Features:

- Receiver-drier is used in systems with expansion valves.

- Accumulators are used in systems with orifice tubes.

- Importance:

Prevents moisture from freezing and blocking the system, protecting components from damage.

6. Refrigerant

- Role:

The working fluid that absorbs and releases heat as it changes states between gas and liquid.

- Common Types:

- R134a: Widely used but being phased out in some regions.

- R1234yf: A more eco-friendly alternative.

- Importance:

Essential for the heat exchange process.

7. Blower Motor

- Role:

Circulates air over the evaporator and into the cabin.

- Key Features:

- Adjustable speeds for customized airflow.

- Importance:

Distributes cooled air efficiently throughout the cabin.

8. Air Ducts and Vents

- Role:

Deliver cooled air from the blower motor to various parts of the cabin.

- Key Features:

- Designed for even airflow distribution.

- Importance:

Ensures effective cooling across the entire cabin.

9. Fans

- Role:

Enhance airflow through the condenser and sometimes the evaporator.

- Key Features:

- Can be engine-driven or electric.

- Importance: Improves heat dissipation and cooling efficiency.

10. Control Panel

- Role:

Allows the driver to adjust temperature, fan speed, and airflow direction.

- Key Features:

- Digital or manual controls.

- May include automatic climate control options.

- Importance:

Provides user control over the cooling system.

11. Pressure Switches

- Role: Protect the system by monitoring refrigerant pressure levels.

- Key Features:

- Low-pressure switch prevents compressor damage due to low refrigerant levels.

- High-pressure switch shuts off the system to prevent overheating.

- Importance:

Ensures safe and efficient operation.

12. Cabin Air Filter

- Role:

Filters out dust, pollen, and other contaminants from the air entering the cabin.

- Key Features:

- Replaceable and essential for clean air circulation.

- Importance:

Enhances air quality and protects the evaporator from debris.

13. Thermostat

- Role:

Monitors and regulates the cabin temperature.

- Key Features:

- Works with the control panel to maintain the desired temperature.

- Importance:

Ensures consistent comfort levels.

14. Auxiliary Components (Optional)

- Electric Cooling Fans:

Provide extra airflow for improved cooling in extreme conditions.

- Solar Panels:

Assist in powering electric air conditioning units without draining the battery.

Key to Optimized Performance

To ensure the bus air conditioner performs at its best:

- Regular Maintenance:

Clean or replace filters, check refrigerant levels, and inspect for leaks.

- System Check:

Test components like the compressor, fans, and pressure switches periodically.

- Use High-Quality Parts:

Invest in durable components to enhance system reliability and longevity.

Understanding these components helps in diagnosing issues, maintaining the system, and making informed choices when repairs or upgrades are needed. As a professional bus AC parts supplier, Kingclima offer 7*24 patient and professional help, if you need, please contact us.

1. Compressor

- Role:

The heart of the air conditioning system, responsible for compressing refrigerant and circulating it through the system.

- Key Features:

- Driven by the bus engine or an electric motor.

- Maintains the refrigerant under high pressure.

- Importance:

Without the compressor, the refrigerant cannot circulate to remove heat from the cabin.

2. Condenser

- Role:

Converts the high-pressure refrigerant gas into a liquid by dissipating heat.

- Key Features:

- Located at the front of the bus, near the radiator, for maximum airflow.

- Uses external air or fans to cool the refrigerant.

- Importance:

Essential for releasing heat and ensuring efficient cooling.

3. Evaporator

- Role:

Absorbs heat from the bus cabin and cools the air.

- Key Features:

- Located inside the cabin behind the dashboard.

- Cold refrigerant flows through the evaporator, cooling the air blown over it.

- Importance:

The primary component for reducing cabin temperature.

4. Expansion Valve or Orifice Tube

- Role:

Regulates the flow of refrigerant into the evaporator.

- Key Features:

- Expansion valve adjusts flow based on temperature.

- Orifice tubes provide a fixed flow rate.

- Importance:

Controls refrigerant pressure and temperature, ensuring optimal cooling.

5. Receiver-Drier or Accumulator

- Role:

Removes moisture and contaminants from the refrigerant.

- Key Features:

- Receiver-drier is used in systems with expansion valves.

- Accumulators are used in systems with orifice tubes.

- Importance:

Prevents moisture from freezing and blocking the system, protecting components from damage.

6. Refrigerant

- Role:

The working fluid that absorbs and releases heat as it changes states between gas and liquid.

- Common Types:

- R134a: Widely used but being phased out in some regions.

- R1234yf: A more eco-friendly alternative.

- Importance:

Essential for the heat exchange process.

7. Blower Motor

- Role:

Circulates air over the evaporator and into the cabin.

- Key Features:

- Adjustable speeds for customized airflow.

- Importance:

Distributes cooled air efficiently throughout the cabin.

8. Air Ducts and Vents

- Role:

Deliver cooled air from the blower motor to various parts of the cabin.

- Key Features:

- Designed for even airflow distribution.

- Importance:

Ensures effective cooling across the entire cabin.

9. Fans

- Role:

Enhance airflow through the condenser and sometimes the evaporator.

- Key Features:

- Can be engine-driven or electric.

- Importance: Improves heat dissipation and cooling efficiency.

10. Control Panel

- Role:

Allows the driver to adjust temperature, fan speed, and airflow direction.

- Key Features:

- Digital or manual controls.

- May include automatic climate control options.

- Importance:

Provides user control over the cooling system.

11. Pressure Switches

- Role: Protect the system by monitoring refrigerant pressure levels.

- Key Features:

- Low-pressure switch prevents compressor damage due to low refrigerant levels.

- High-pressure switch shuts off the system to prevent overheating.

- Importance:

Ensures safe and efficient operation.

12. Cabin Air Filter

- Role:

Filters out dust, pollen, and other contaminants from the air entering the cabin.

- Key Features:

- Replaceable and essential for clean air circulation.

- Importance:

Enhances air quality and protects the evaporator from debris.

13. Thermostat

- Role:

Monitors and regulates the cabin temperature.

- Key Features:

- Works with the control panel to maintain the desired temperature.

- Importance:

Ensures consistent comfort levels.

14. Auxiliary Components (Optional)

- Electric Cooling Fans:

Provide extra airflow for improved cooling in extreme conditions.

- Solar Panels:

Assist in powering electric air conditioning units without draining the battery.

Key to Optimized Performance

To ensure the bus air conditioner performs at its best:

- Regular Maintenance:

Clean or replace filters, check refrigerant levels, and inspect for leaks.

- System Check:

Test components like the compressor, fans, and pressure switches periodically.

- Use High-Quality Parts:

Invest in durable components to enhance system reliability and longevity.

Understanding these components helps in diagnosing issues, maintaining the system, and making informed choices when repairs or upgrades are needed. As a professional bus AC parts supplier, Kingclima offer 7*24 patient and professional help, if you need, please contact us.

Previous Post

Related Post

.jpg)